Your Jungheinrich racking for maximum customer benefits.

Flexibility

Racking as individual as your business.

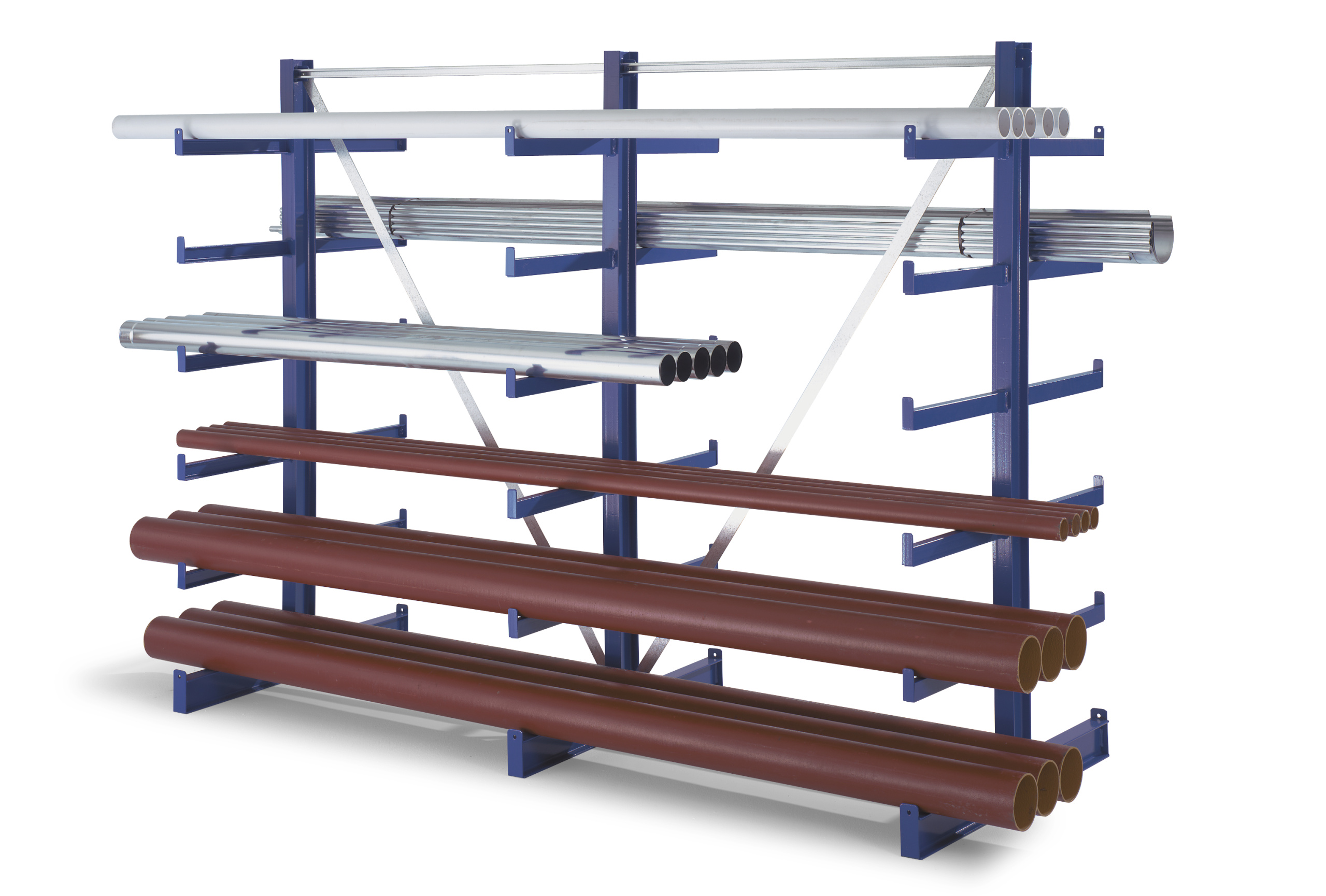

The design and transport system of the drive-through racking can be adapted to a whole host of warehouse environments and ranges of goods. You can remain flexible when your requirements change.

* Optimum adaptation capability

- Installation in pallet racking or free-standing.

- Integration at double-rack depth and single-rack depth.

* Individual configuration

- Adjustable height and tilt angle.

- Flexible channel distribution thanks to guide rails for products with different dimensions.

Efficiency

Everything you need for optimum material flow.

The load slides down for automatic replenishment by an inclined roller conveyor to save time and energy. Order picking performance is also boosted by short routes and a clear overview of the storage.

* Space saving

- Compact storage.

- No operating aisles.

* Efficient order picking

- Simple workflow and optional pick-by-light systems prevent order picking errors.

- Savings in travel time.

- Reduced throughput times.

Safety

Best conditions for working safely.

Our preventive services and the appropriate racking accessories ensure that people, trucks and racks all stay safe ñ in every situation. So your processes can keep flowing and your capital goods remain protected.

* High process reliability

- Simple monitoring of batches and best-before dates.

- Segregated storage possible.

.png)