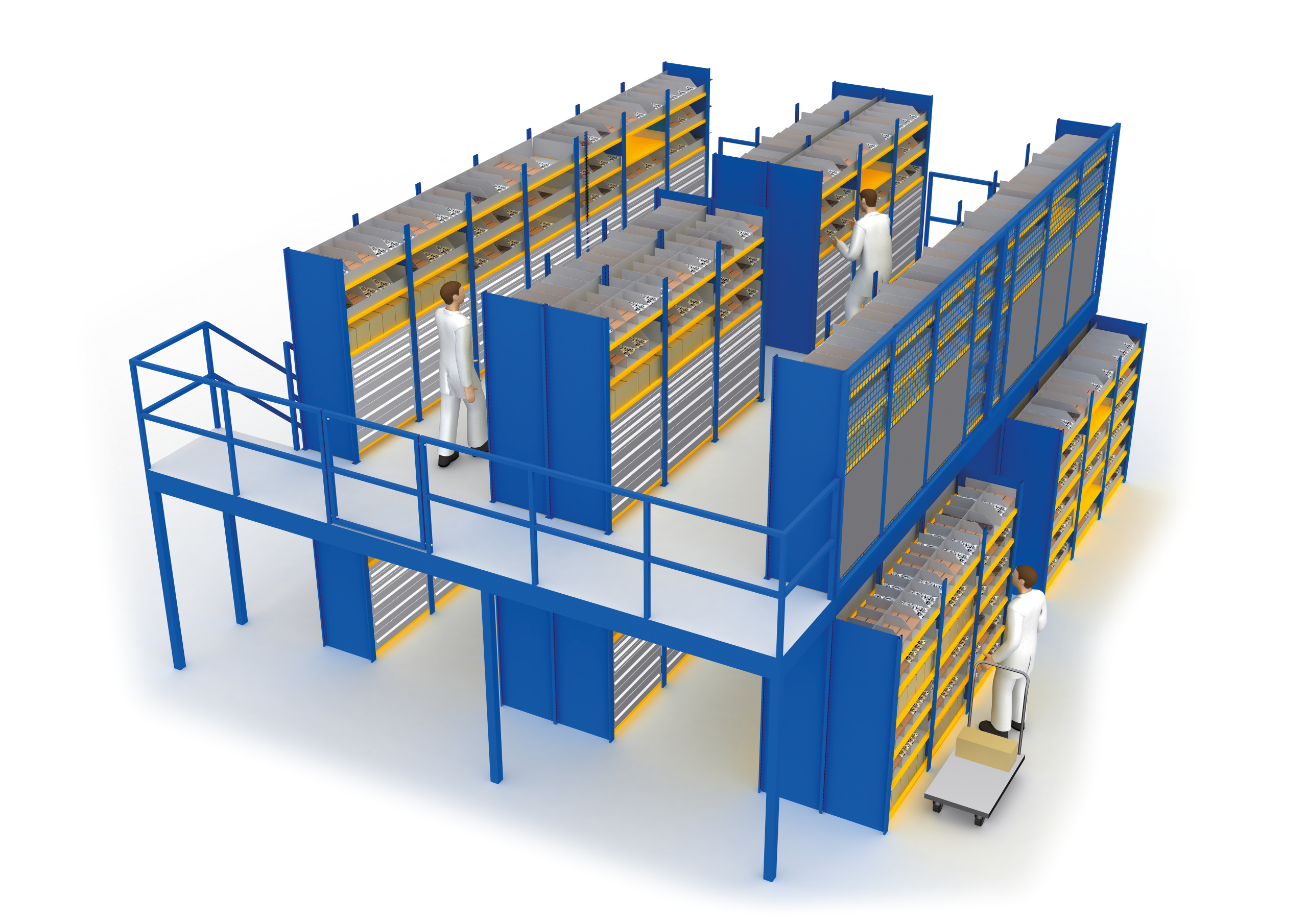

Your Jungheinrich shuttle for maximum customer benefits.

Efficiency

Strong solutions for the optimum flow of materials.

Ensure maximum utilisation of space in your warehouse with a compact shuttle solution. Independently running shuttles work in parallel with your industrial trucks and ensure space-saving storage and perfect time management.

* Increased utilisation of space

- Compact storage enables more pallets to be stored in the same footprint.

- Optimum volume utilisation with a fill level of up to 90%.

- Smallest possible racking compartment heights due to

the low overall shuttle height of 145 mm.

* Optimum energy efficiency

- Improvement of the energy balance due to the compact construction.

- Optional energy-saving mode.

- Suitable for use in the deep- freeze store.

* Economical two and three-shift operation

- Guaranteed operating period of 8 to 10 hours with fully charged battery pack.

- The battery trays enable batteries to be changed in seconds.

- Separate battery charger for easy charging at any 230-V mains socket.

* Greater reliability

- Round-the-clock availability of more than 4,700 Jungheinrich service engineers worldwide.

- 98% spare part availability with overnight delivery option.

Safety

Best prerequisites for working safely.

Best equipped for all applications: preventive protection mechanisms and selected racking accessories guarantee maximum safety for employees, trucks and warehouse equipment ñ so your processes always flow smoothly.

* Conformity with standards

- All Jungheinrich shuttle systems fulfil the applicable standards and directives.

* High quality and safety standard

- RAL quality seal: regular inspection of quality and safety according to stringent guidelines by an independent institute.

- Independently conducted inspections at the production facilities ensure constant quality at all sites worldwide.

* Safety equipment for safe working

- Comprehensive safety equipment such as impact protection bars, sensors for obstacle and overhang detection, emergency stop to guarantee reliable and safe shuttle operation.

- Optional equipment with pallet stops, side gratings and bumpers for optimum protection of the goods.

- Optional integration of stationary aisle protection system.

Individuality

A shuttle as individual as your business.

Tailored to your requirements: our wide selection of shuttle types, in combination with optional functions and accessory parts, enables you to use our warehouse solutions individually ñ guaranteeing maximum productivity.

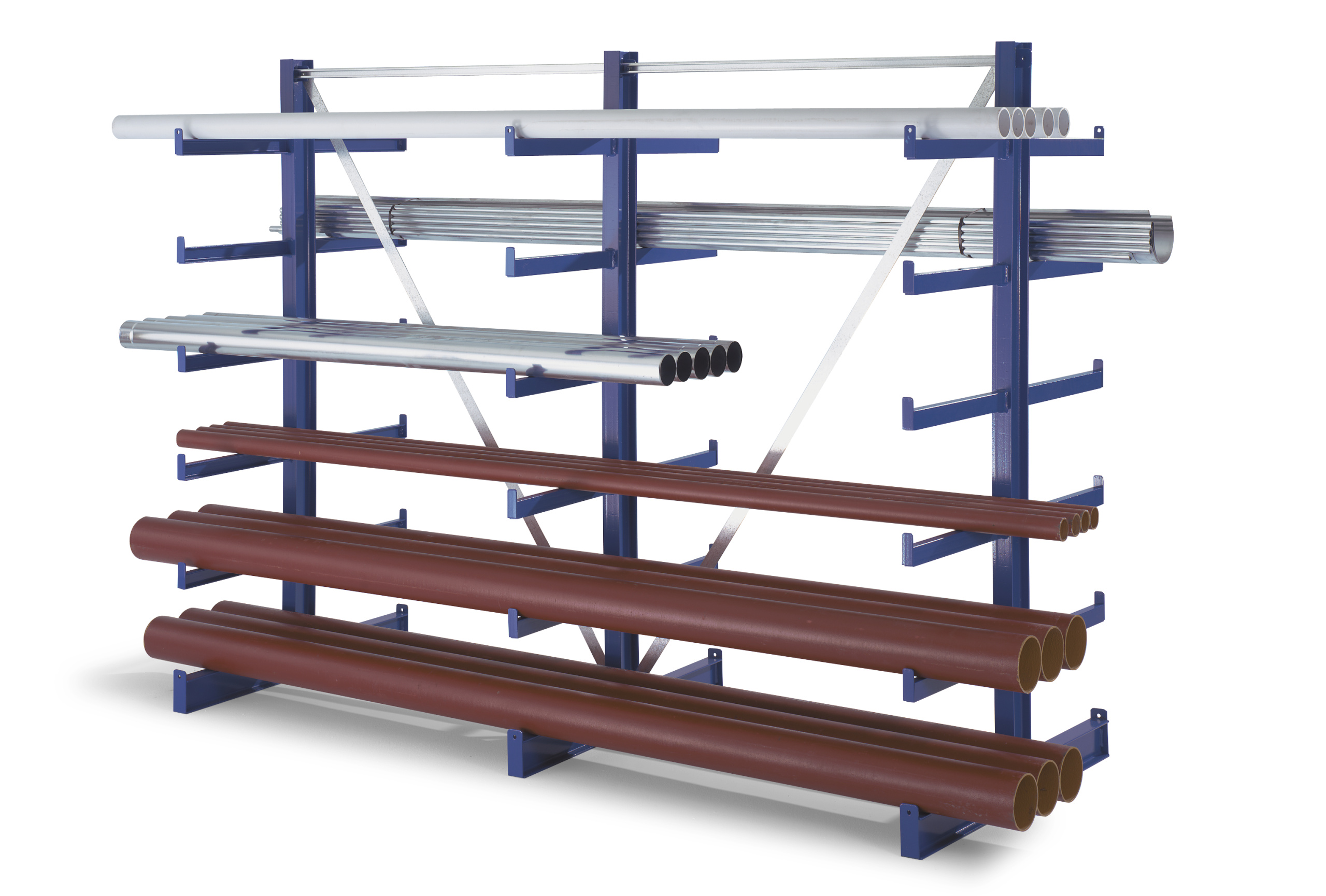

* Various load carriers

- Euro pallets.

- Industrial pallets.

- Chemical pallets.

- Euro and industrial pallets in the same racking system: combination shuttle with sensors for detecting the pallet size.

- Other variants available on request.

* Flexible warehouse strategy

- Suitable for FIFO and LIFO principle (also as retrofit).

* Different applications

- Can be operated with a wide range of industrial trucks.

- Can be used problem-free in deep-freeze down to -30∞C (optional).

* Optional functions

- Virtual channel separation for the LIFO operation of both channel sides, each with one shuttle.

- Compression: time-saving storage or removal, e.g. at shift end.

- Multiple removal: automatic removal of a predefined number of pallets or the entire channel.

.png)