Your Jungheinrich racking for maximum customer benefits.

Efficiency

Everything you need for optimum material flow.

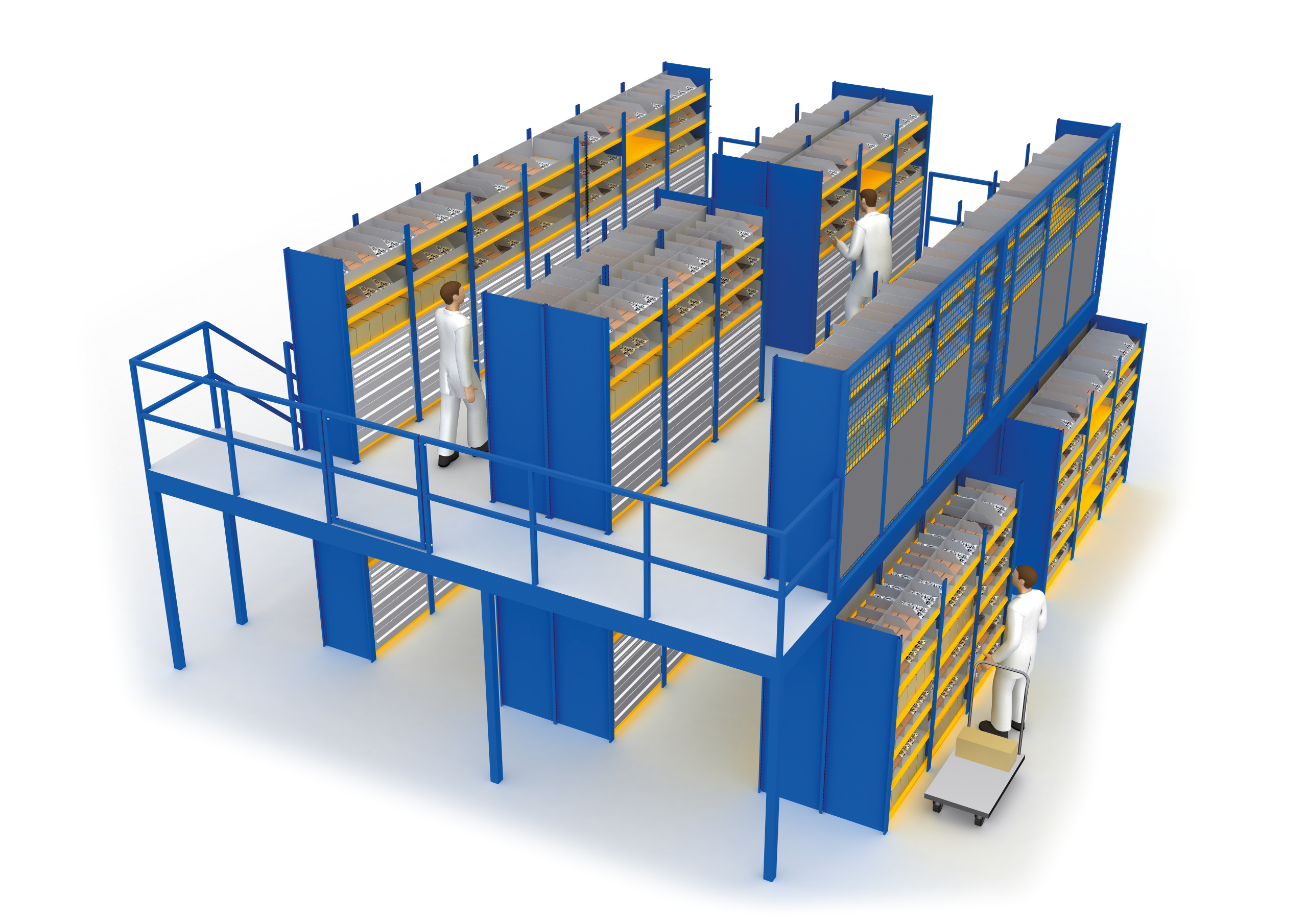

A racking system dimensioned to meet actual needs optimises the efficiency of the entire material flow. The pallet racking systems adapt to the space available. A compact storage method enables a high utilisation of space.

* High utilisation of space

- No aisles between the racking rows.

- The space saved can be used for storage purposes.

* Efficient working

- The ideal storage system for seasonal goods.

Safety

Best conditions for working safely.

Our preventive services and the appropriate racking accessories ensure that people, trucks and racks all stay safe ñ in every situation. So your processes can keep flowing and your capital goods remain protected.

* High-quality Jungheinrich pallet racking

- Independent test rigs at the production facilities ensure constant quality at all sites worldwide.

- RAL quality seal: Regular inspection of quality and safety according to stringent guidelines by an independent institute.

* Safety accessories

- Fast and safe channel entry through the installation of guide rails in the ground.

- Entry aid for support rails.

- Upright protection and entry guide for precise control.

- Pallet end stop as back stop.

Flexibility

Racking as individual as your business.

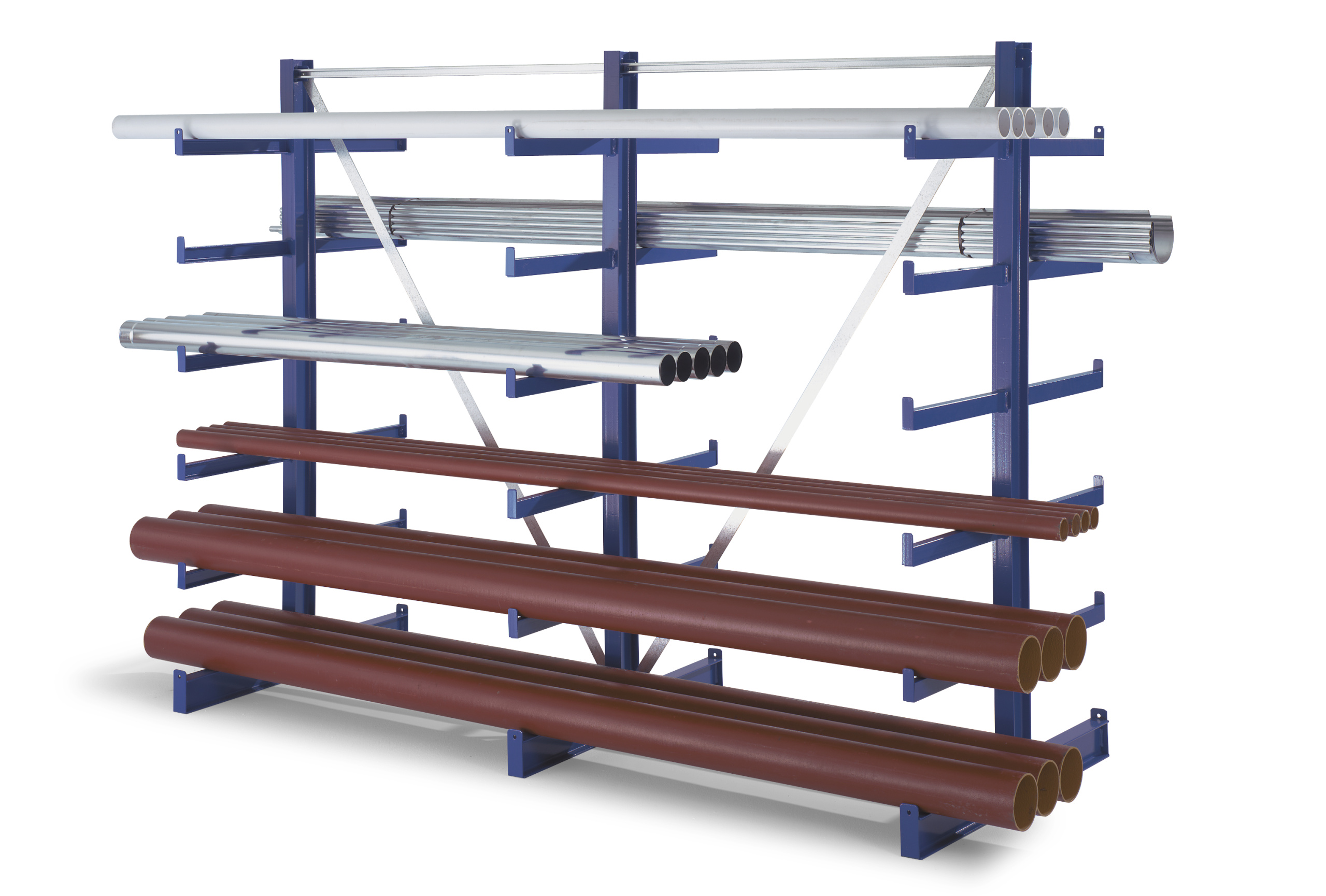

Should your requirements change, the system design makes it quick and easy to convert the pallet racking. It is suitable for storing items and materials of various sizes and can be operated using suitable trucks.

* System principle

- Standard structural elements employing the modular principle.

- Can be combined with other Jungheinrich racking.

* Comprehensive range of accessories

- Guide rail on the ground.

- Pallet entry aid.

- Markings.

* Individual sector solutions

- Advice from experts with sound sector experience.

- Tailored solutions for various sectors, e.g. grocery sector, wholesale, production industry and many more.

.png)